Mining Museum - Tumblr Posts

Namibia/Südafrika 2017/18 - Teil 11

Mittwoch, 20. Dezember 2017,

Herrschaften und Oukies!

Heute Morgen haben wir uns von unseren wirklich zauberhaften Gastgebern, Charmel & Ross, der Chapmans Safari Game Lodge verabschiedet.

Selten haben wir eine so umwerfende, herzliche Gastfreundschaft erlebt. Toll! Mit nur 8 Gästezimmern ist diese Unterkunft wirklich sehr persönlich.

Schade, dass die Lodge in absehbarer Zeit verkauft wird. Die Eigentümer wollen sich auf Sansibar niederlassen.

In etwa 3 Stunden Fahrzeit war unser nächstes Etappenziel, das Protea Hotel der Marriott-Gruppe in Kimberley, erreicht.

Kimberley, die Stadt mit dem schönen Beinamen "The city that sparkles", ist die Hauptstadt und mit ihren knapp 200.000 Einwohnern zugleich auch die größte Stadt der Provinz Northern Cape.

Hier wollten wir vor allem das Big Hole besichtigen.

Doch die Stadt hat noch eine Besonderheit zu bieten: hier gibt es eine zwei Kilometer lange Straßenbahnstrecke, damit fährt in Kimberley die einzige Straßenbahn in ganz Südafrika.

Sie wurde 1887 in Betrieb genommen und dient heute vor allem den Touristen als Fortbewegungsmittel.

Wenn man das Big Hole sehen möchte, so kommt man automatisch auch zum Kimberley Mining Village, ein Freiluftmuseum im Zentrum der Stadt.

Gegenüber befindet sich ein Parkplatz, von dem aus man durch eine Unterführung den Komplex erreicht. Direkt daneben befindet sich der Eingang zum Big Hole und zum Kimberley Mine Museum.

Das Mining Village ist täglich geöffnet und kostet keinen Eintritt. Hier wurden die alten Häuser von Kimberley um das Jahr 1880, zur Zeit des Diamantenrausches, originalgetreu nachgebaut.

Man kann schön im Schatten der Häuser durch die Straßen schlendern und überall hineinsehen. Sie sind liebevoll ausgestattet mit allerlei alten Dingen.

Es gibt voll eingerichtete Wohnhäuser, einen Tabakladen, ein Ballhaus, Barnato's Boxing Akademie, eine alte Arztpraxis, die alte Schmiede, das Büro für Goldankauf und einige Geschäfte und Pubs.

Das älteste Haus wurde 1877 aus England importiert und war damals der reine Luxus, denn die meisten Arbeiter wohnten in Zelten oder notdürftig zusammen gezimmerten Hütten.

In einigen Häusern werden heute noch Erfrischungen oder Souvenirs verkauft und mitten drin kann man sogar in einem B & B wohnen. Das Restaurant "The Ox" ist sogar bis 22 Uhr geöffnet.

Erstaunlicherweise ist hier auch an die Rollstuhlfahrer gedacht worden. Überall sind Rampen anbetoniert und es gibt auch entsprechend ausgeschilderte Behindertentoiletten.

Das Protea Hotel mit seinen 94 Zimmer liegt direkt nebenan und verfügt über einen eigenen Seiteneingang zum Village, sowie ebenfalls einer eigenen Aussichtsterrasse auf das Big Hole.

So kann man diese Sehenswürdigkeiten auch als "Fußkranker" hervorragend, ohne das Auto bewegen zu müssen, erkunden.

Zwischen der City Hall und dem Kimberly Mine Museum verkehrt täglich zwischen 9:00 und 16:00 die historische Stadtbahn, die Kimberley Tram. Wir haben sie leider noch nicht in Aktion gesehen.

Dafür sieht man einen abgestellten Wagon auf dem Gelände des Museums. Es handelt sich um den De Beers Railway Coach, der von Cecil John Rhodes genutzt wurde, um zwischen Kapstadt mit Kimberley zu pendeln.

Heute Abend werden wir im Hotel essen und morgen früh, nach dem Frühstück, wollen wir uns dem Big Hole Komplex und dem Diamantenabbau widmen.

Recht herzlichen Dank für die Aufmerksamkeit und lekker Slap!

Angie & der Monsieur le Chauffeur & der Hasenbär

Witten: The Nachtigall colliery (Zeche Nachtigall)

- English -

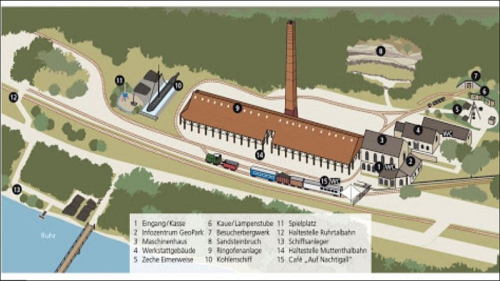

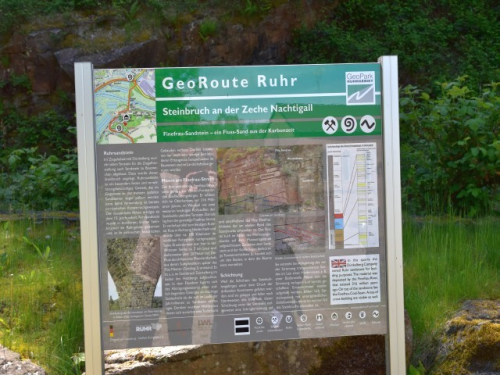

The Nachtigall colliery is located directly on the river Ruhr in Witten. The museum is part of the Westphalian Industrial Museums and shows 300 years of industrial history. The pioneering era of mining comes to life at the Nachtigall colliery in the Witten Ruhr valley.

The location is ideal: right next door is the mine and field railway museum on the former Theresia colliery and on the other hand the very scenic Muttental opens up. As is well known, this was the cradle of Ruhr mining and many remains still testify to this time. This epoch comes to life again on a remarkable tour of mining history.

The farmers in this area had been digging for coal for their own use for centuries. The Nachtigall colliery was founded in 1714. This year, two farmers were given the right to mine coal in the Coal Bank in Hettberger forrest. For a long time, the coal mining was limited to digging holes, the so-called ping. However, damage to the land by ping extracting partially affected agriculture considerably.

In 1743, about 29 years later, the Baron von Elverfeldt acquired the right to mine hard coal for the Nachtigall colliery. The coal was mined in small businesses with three to six men. In the middle of the 18th century, the first tunnel was built.

Water entering the tunnels was discharged through stollen to the river Ruhr. In addition to the water supply, such stollen also discharge the mine gases, supply fresh air and sometimes also transport coal.

The miners often keep goats and pigs for self-sufficiency and grow vegetables, potatoes and fruit. Plums in particular are dried into dried fruit, which often gives workers the name "Prumenkötter".

Since then, the coal mine has been called "Nachtigall am Hettberg". Winders had been used for a long time to extract coal. The drive is initially provided by humans and horses.

At the turn to the 19th centuries, the transition from tunneling to civil engineering was made at the Nachtigall mine with the help of steam engines. This was only possible through a merger of the mine owners, who could raised the capital for the changeover in this way.

The Nachtigall colliery was one of the first to move from tunnel construction to civil engineering. In 1829 a 6 km long railway for coal transport with horse drive was built. It leads to the coal deposition, south of the road to Wuppertal and the Bergisches Land as well as the Siegerland, to supply the ironworks.

To the north, the Muttental railway leads to the coal deposition on the river Ruhr. As early as 1780, the Ruhr area was navigable from Herdecke to the Rhine - a great relief for coal transportation, which had previously been carried out over long distances with wheelbarrows and horses.

Steam engines soon solved the water drainage problem. They also make it possible to mine coal below the water level of the river Ruhr. In 1832 the first underground shaft of the Nachtigall mine was sunk.

In order to be able to raise the huge amounts of capital required for this, several small mines in the area of Nachtigall come together and establish a company. In 1844, the Nachtigall colliery was the largest in the Ruhr area. In the middle of the 19th century, around 300 to 500 people worked here at depths of up to 450 meters.

A bridge over the river Ruhr, the Nachtigall Bridge, connects the Nachtigall colliery to the Witten-West train station. The connection lies on the Bergisch-Märkische Railway, which opened in 1848.

Coal transport is further facilitated as a railway line runs through the Ruhr Valley from 1874. A separate freight station will soon ensure smooth transportation to and from the coal mine.

In 1890, around 880 miners worked at the Nachtigall colliery. In order to keep the coal price stable and to avoid overproduction, the production volume for the individual mines in the Ruhr area is quoted.

The larger collieries north of the river Ruhr buy up the almost unprofitable collieries in the Muttental in order to be able to mine larger quantities overall. In addition, the coal in the Witten area, unlike the fat coal in the northern areas, is not suitable for coking. In some seams, the supply is also exhausted.

In 1892, the operation of the Nachtigall colliery was stopped after a major water ingress. Most of the miners were housed in the mines of the northern mining region or in other industrial companies. The cessation of mining operations and water management on the colliery is followed by the flooding of the civil engineering mine. However, some pits and tunnels remain water-free, which will be important later on.

The site was then taken over by the entrepreneur Wilhelm Dünkelberg. Dünkelberg had ring ovens built for a steam brick factory above the mine shaft. Brick production on the nightingale began in 1897 as a successor to the mining operation.

She used a dry tunnel through the mountain for the direct transport of raw materials from the quarry to the brick kiln, in this case a double ring kiln with the noticeable and distinctive chimney. The brick press designed by Dünkelberg becomes an export hit - it is sold as far as China.

The brickworks on the grounds of the Nachtigall colliery closed in 1963. A car recycling company and a wreath binder moved in - but only for a short time. The buildings are decaying more and more, the colliery houses are demolished in 1966. In the 1970s, the past was remembered and awareness of the importance of industrial culture began to develop.

In 1983 the landscape association Westfalen-Lippe took over the Nachtigall colliery to the Westphalian Industrial Museum (WIM). Since then, the Nachtigall mine has been restored for over 20 years and officially opened in 2003.

Today the visitor experiences the industrial and traffic history of the Ruhr area. The partially accessible double ring kiln of the former brick factory is particularly impressive. Here you almost feel reminded of old castles and medieval fortifications. A coal ship has moored in the grounds, outside on the premises. Coal used to be transported across the river Ruhr on these sailing ships.

In the exhibition around the filled up “Hercules” shaft from 1839 - one of the first underground shafts in the district - guests learn about the technology and difficult working conditions of the miners in the 19th century.

For many, the absolute highlight of their visit is a visit to the old mine. Like the miners of that time, visitors can explore the tunnel with a helmet, a miner's jacket and a lamp. Former miners tell of the harsh conditions under which the miners once brought the "black gold" to light.

Interested people get to know the work with compressed air drill and mining hammer during the mining trip and can get their own impression of how things are going inside a coal mine.

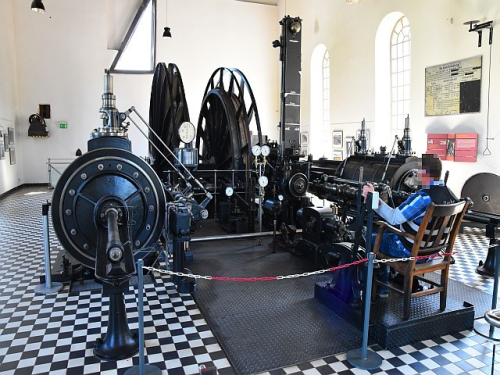

You can find out about the mining history of the Ruhr Valley in the three surviving factory buildings of the colliery. The main focus is on the origin of coal, the industrial development of the Ruhr Valley, coal consumption, Ruhr shipping and the description of the miner´s job about 150 years ago. A steam Winding engine that has been preserved can even be inspected in operation.

Behind the machine house is the outdoor area with the exhibition "Coal in buckets". A tripod was set up here, which used to be used to extract the coal in buckets from the shaft and load it directly onto carts or wagons.

A primitive booth protects the associated reel system. The facility is surrounded by various small huts with coe and lamp room. There is a quarry at the southern end of the site.

The visitor can inspect the clearly, but lovingly designed area . Most of the exhibits are in closed rooms, which is why a visit in rainy weather is also not a problem. A small café is attached to the museum.

Opening hours Tuesday – Sunday and public holidays 10 am–6pm Last entry at 5:30 p.m.

Closed: Mondays (except public holidays) and from December 23 to January 1.

Entrance fees

Free admission for everyone on the “Museum Days” Children, adolescents and school pupils are free all year round

Adults 4.00 €uros Groups of 16 people or more 3.50 €uros / pp Reduced 2.00 €uros

The entrance prices apply without visit the mining tunnel. Including tunnel admission, the price per ticket increases by 3 €uros, children from 5 years of age pay 1.50 €uros for the tunnel tour.